Alpine DMG Solutions Inc.

Cleaning-In-Place (CIP) Systems

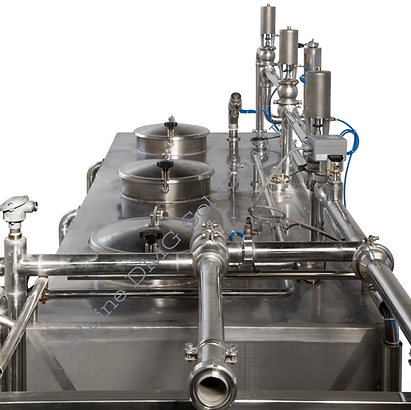

CIP Systems

The Cleaning-In-Place systems (CIP systems) are designed for automatic cleaning and disinfection without major disassembly and assembly work. The technology is important for the dairy and other food industries, in which processes must take place in a hygienic environment.

CIP systems use chemicals and cleaning agent formulas to clean and sanitize the processing equipment.

Based on your production or processing requirement, double, triple or more number of tanks can be mounted on the system. With our custom-designed CIP systems, simultaneous washing of multiple lines is possible with manual, semi-automatic and full-automatic operations.

Our pre-fabricated CIP units are designed for optimal cleaning solutions and can be delivered skid-mounted and ready to be incorporated on site.

.jpg)

Based on your processing application needs, our semi-automatic and full-automatic CIP systems may include: acid tank, alkaline tank, water tank, heating system, control system, etc.

They are also equipped with a PLC controller and a touch-screen panel that are very easy to use. Cleaning programs can be saved and many parameters such as: the type of washing, temperature, times of washing and cleaning cycles, concentration of acid/alkaline solutions, etc. can be reliably selected with precision.

With our custom-designed CIP systems, simultaneous washing of multiple lines is possible.

All our CIP Units come with standard features including hinged manholes, adjustable legs and feet.